One of the biggest frustrations for a maintenance directors of warehouses is damaged concrete joints. They not only slow down production for forklift travel, but they are dangerous, cause damage to forklifts, and can result in lost or damaged product. Often times these joints are patched over and over again with epoxies, but the patches fail and the problem persists and typically worsens.

Is there a right way to repair damaged concrete joints?

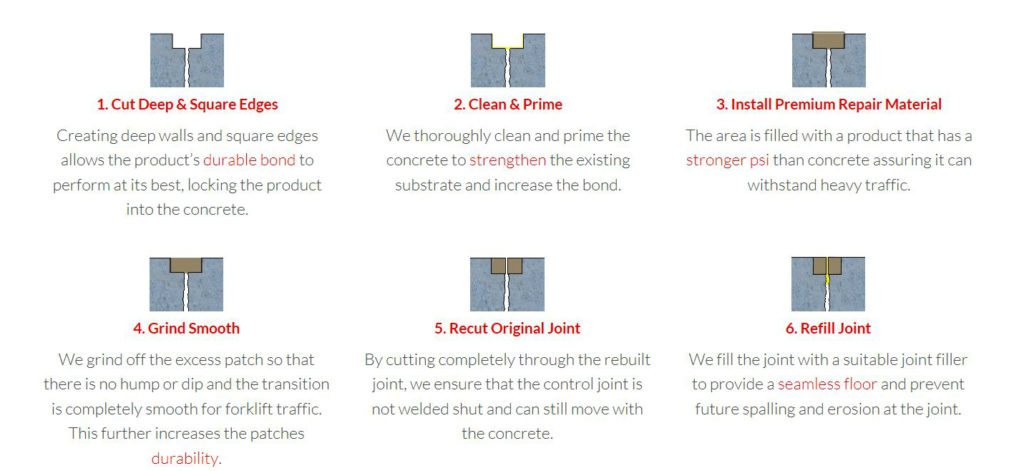

From moderate to severe concrete joint damage there is a right way to repair them! If done properly this method should result in a lasting joint repair that can withstand heavy industrial traffic. Below is an outline of the proper method to repair damaged concrete joints. This method can be performed for joints that are damaged from 1/2″ wide to 5 feet wide or even more. By using these proper methods for concrete joint failure, your warehouse can end frustrations of maintenance, repair, and increase productivity.

Proper materials for damaged concrete joints:

Standard epoxies are not designed for heavy industrial traffic in warehouses. This is why most of the time they fail – over and over again. The proper products are reactive resin mortars. A specialty concrete repair contractor will be familiar with these unique products that have an incredible bond and a compressive strength greater than the concrete itself.

Find out more information on Titus Restoration’s Concrete Joint Repair Services here.