Tired of putting a bandaid on concrete spalling and other minor concrete repairs? Looking for a lasting solution for concrete floor cracks or minor divots? Concrete spalls (or chips and divots) is a very common concrete floor issue in warehouses and other industrial facilities. If they are addressed quickly, and properly, they can become a bigger headache (and a more costly one) down the road. Repair these concrete trip hazards before they get out of hand – and for good!

Lasting concrete spalling and crack repair:

There are 2 key elements to any lasting or permanent concrete repair. They are product and prep.

The first is a bit easier than the second. If you are buying your product from a hardware store or home improvement store it is probably not suitable for an industrial operation. Go a step further, check out a industrial concrete repair manufacturer or retailer. Even the products labeled “industrial strength” at your local home improvement store are not going to be suitable! You are looking for something reinforced with an epoxy, polymer, or other synthetic without fillers. These are going to be high dollar products and thus are not carried on the shelf at such retailers.

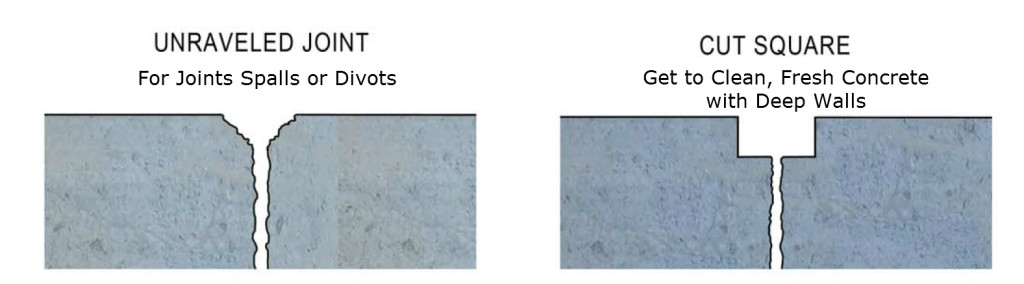

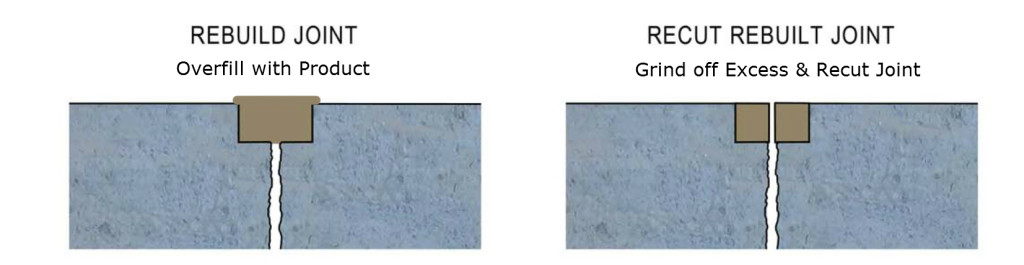

The second is where a lot of facility managers are failing to properly address the repair from a structural standpoint. First, read the data sheet on the product you have selected. Does it describe in detail how to install? Are there temperatures and mixing times for installation? Following the directions precisely are very important. But more importantly than that is preparing the substrate to receive the repair product. Here are some tips:

Titus Restoration has been repairing concrete spalling and cracks for decades. Our products are top of the line (we buy in bulk to get the best value), and our preparation are sound and ensure lasting concrete repairs. Check out some of our repairs jobs here.