Looking for ways to end the on-going frustration of concrete slab repair? Warehouse and plant managers are often plagued with failing concrete repairs in their facilities. Learn the main reasons why these repairs don’t last and how to stop them for good! You can also read more about industrial concrete repair here.

Top 3 Reasons Concrete Slab Repair Fails:

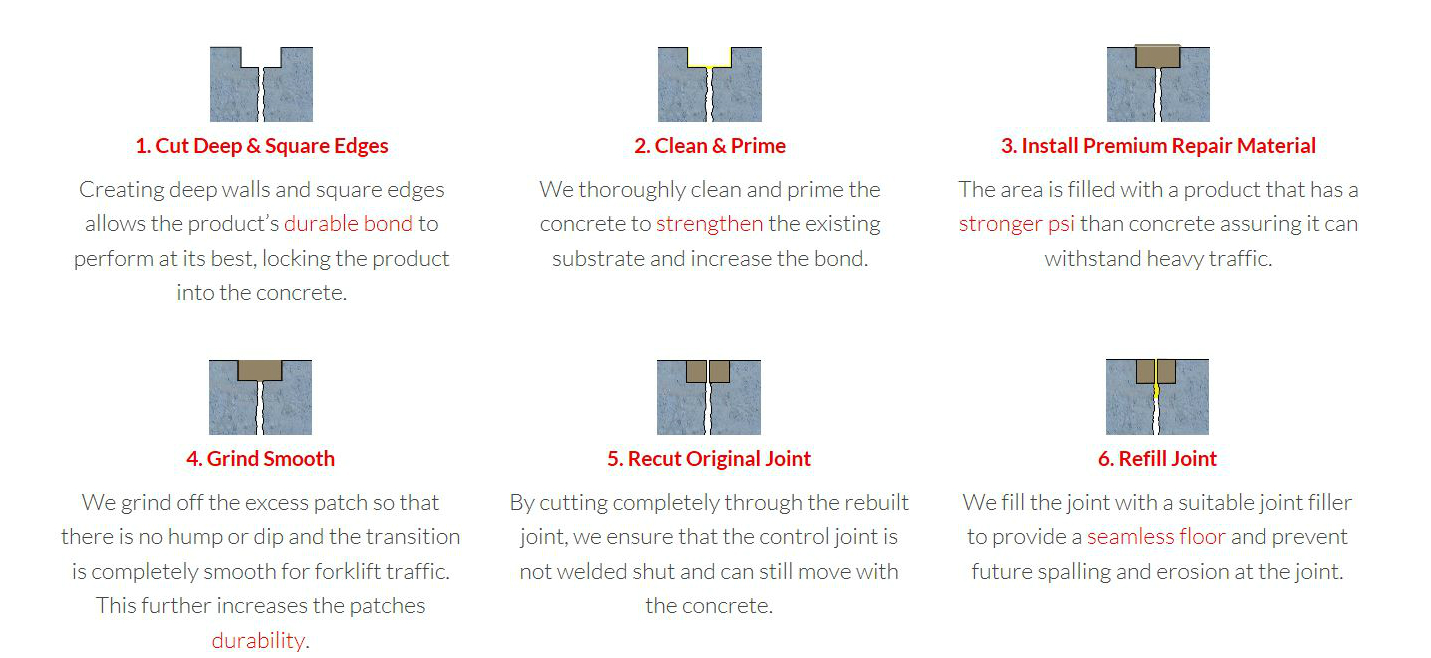

- Improper Preparation – For concrete repair materials to work properly, extreme care must be taken with the concrete surface preparation. Getting to clean, bare concrete is step one. Deep edges is another must for the product to be fully locked into the slab. Finally, if the slab is soft and the concrete crumbles away easily, it must be reinforced and strengthened with a deep-penetrating primer. These primers give the repair material something to bite to; however, a repair is only as good as the substrate it is on top of and a deeper patch may be recommended if the concrete is extremely weak. Failing to clean the concrete, give it deep square edges for the material to bond to, and failing to look for a weak substrate is the number one reason concrete slab repairs fail quickly.

- Wrong Materials – Concrete slab repair materials vary in price range and quality drastically. Most of the time epoxies are used to fill divots and cracks and these epoxies are laden with fillers that do not bond well with the concrete (especially is surface prep isn’t performed properly) leaving the repair to fail days or weeks later. Further, size of the repair should be considered as the exothermic reaction in epoxy will affect its integrity. In addition, working times with these products is extremely important to their effectiveness. Choosing quality products – preferably stronger than concrete – is key to a great repair.

- Not Flush with Concrete – Creating a seamless transition is so important in concrete slab repair (see number 4 in the diagram below). If there are dips or humps in the repair, it will surely fail because it is giving wheeled traffic a point of impact. These points of impact start to slowly deteriorate and before you know it the entire patch has failed. Overfilling the patch and then grinding it smooth and flush with the concrete surface not only locks the product into the slab, but prevents any points of impact from causing damage.

Example of a Warehouse Concrete Joint Rebuild Repair:

Certified Concrete Slab Repair Specialist:

Titus Restoration is certified to tackle some of the most challenging concrete slab repair projects from rocking slabs and sub slab voids to surface damage and joint rebuilding. Our products are of the highest quality and our crews are trained and certified to perform challenging tasks. Contact our estimators today for more information on your damaged slab repair project.